Are you tired of compromising your safety while working with hazardous chemicals? Discover the ultimate solution to protect yourself with the best chemical resistant boots available in 2025! Say goodbye to worries and hello to peace of mind in the workplace!

Chemical resistant shoes are essential for individuals who work in industries where exposure to dangerous chemicals is a regular occurrence. Not only can chemicals wreak havoc on footwear, rendering it useless in no time, but their direct contact with the skin can lead to severe allergies. These boots provide a protective barrier against harmful substances, ensuring the safety and well-being of workers.

Whether you’re a professional in the chemical industry or someone who wants to prioritize safety at work, this guide will help you make an informed decision when choosing the best work boots that are chemical-resistant.

What shoes to wear when working with chemicals?

Wearing footwear specifically designed for chemical resistance is crucial when dealing with potentially hazardous substances. Regular shoes cannot handle chemical challenges, so chemical resistant boots are the ideal choice.

I am giving a list of the most common chemical resistant shoes

used for work in unsafe environments.

- Steel-toe boots

- Muck Boots

- Timberland chemical-resistant boots

- XTP 15 chemical-resistant boots

- Neoprene boots

- PVC boots

- Rubber boots

- Polyurethane boots

- Nitrile boots

- Polymeric boots

This list places paramount importance on safety. Equipped with reinforced toe caps, these boots guard against the perils of falling tools and heavy objects, providing a shield for vulnerable toes. They are equipped with cutting-edge traction technologies, allowing for unrivaled grip on slippery surfaces and lowering the danger of dangerous slips and falls.

Even though these problems may seem significant, they are not impossible to solve. I will find the best chemical resistant work boots resistant to harmful factors and not leave any stone unturned.

Comparison Table – Best Chemical Resistant Boots

To start our exploration, let’s look at a table showcasing the top 10 chemical-resistant boots for work in 2025.

Material, resistance, Durability, and comfort are only some highlights that may be quickly reviewed. Make use of this table as a guide in making decisions:

What are the Best Chemical Resistant Boots in 2025? [Top 10 Picks!]

The need for chemical-resistant shoes or boots becomes paramount when considering the potential consequences of inadequate protection. The importance of reliable footwear in this line of work cannot be overstated.

Through rigorous trials and meticulous scrutiny, I have curated a collection of chemical resistant work boots that will rise above the rest. These boots have been specifically designed to withstand the corrosive effects of chemicals, offering a robust barrier against harmful substances. Their exceptional durability makes them resilient, even in the most demanding work environments.

In this article, I’ll explore the best chemical resistant boots for work available in 2025, their features, their use of testing methods, and their benefits. I’ll give satisfying answers to your queries regarding chemical resistant boots’ specifications.

I’ll discuss the top 10 chemical resistant boots in-depth following the comparison chart. Here you will check:

- The pictures

- Links to Amazon

- Specifications

- Features

- Reviews

- Ratings

- Pros & Cons of each shoe

You will finish this section with a thorough comprehension of the optimal choices now on offer!

1- Dunlop Safety Insulated Chemical Resistant Waterproof Work Boots

Specification

- Polyurethane sole

- Flexible Purofort (PU) upper

- Steel toe

- Removable insole

- The shaft measures approximately mid-calf from arch

Features

- The iconic boot for (semi) solid contaminated areas

- Energy-absorbing heel design for extra ergonomic support

- Extra smooth finish for easy cleaning

- Specifically designed for orthopedic insole

- Thermal insulation down to -50°c/-58°f with a heat-retaining outsole

- uncompromised protection under cold conditions

- lightweight design for minimizing foot fatigue

- Highly abrasion resistant

- Wear and tear-resistant

- Thermal insulation

- Extra smooth design and upper easy to clean

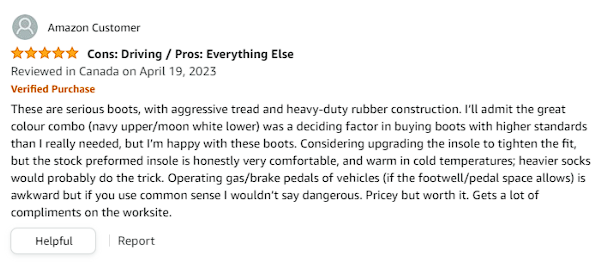

Customer Reviews and Scores!

- Orthopedic insole design

- Wear & tear resistant

- Flexible and lightweight

- Heavy-duty Rubber material

- No cons found

2- Servus XTP 15″ PVC Chemical-Resistant Steel Toe Boots!

Specifications

- Molded PVC with Triple Density Technology

- Outer Material: Synthetic

- Degradation from many harsh chemicals;

- Seamless and 100% waterproof

- FOOT FORM contour cushion insole

- Steel toe impact protection

- Reinforced at critical stress points for extended durability

Features

- Removable, washable, and replaceable insole

- 100% Waterproof

- Chemical-Resistant

- All-Day Comfort

- Excellent Slip-Resistance

- Exquisite arch and heel support

- A thick, wide steel shank supports the arch

- Dual-compound center sole offers compound cushioning

- Open pattern outsole

- Self-cleans liquid and debris with every step

- The outsole perimeter is formulated for challenging, long-wearing support

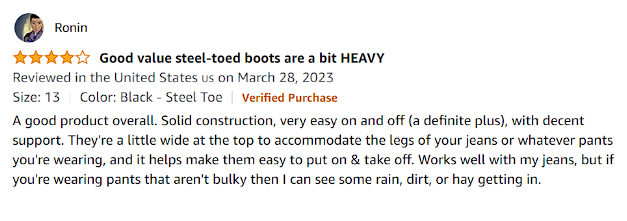

Customer Reviews and Scores!

- Thick sole

- Great fit

- Steel toe for safety

- Self-cleaning material

- Chemical & debris resistant

- Comfy insole

- Size issues

- Not 100% wear & tear resistant if used daily

- Not completely odor-Free

- Sweaty insides in warm surroundings

3- Servus MAX 15″ PVC Chemical-Resistant Soft Toe Unisex/Women’s Boots

Specification

- Solid outer pattern

- Injection molded PVC with Triple Density Technology

- Wide steel shank

- Cushion bed sole

- FOOT FORM contour insole

- High heels

Features

- 100% waterproof

- Chemical resistant

- Arch support shape

- Calves Protection

- Debris-free premium material

- Lightweight

- Self-cleans liquid and debris

- Higher, wider kick-off lugs for easy on/off

- Tough, long-wearing support

Customer Reviews and Scores!

- Unisex shoes

- Rigid material for chemical resistance

- Extended length for legs protection

- High heels for comfy walks in mud or water

- Insole cushioning for more extended wear

- Stress-Free walks

- Narrow toe

- Not a long-run player

4- DUNLOP Mens Modern Industrial Chemical Resistant Steel Toe Boots

Specifications

- Vibram outsole

- SRC-rated, with a strong grip

- Purofort premium material

- Expendable shape

- Cold insulation

Features

- Made with Purofort material, a unique recipe, and a molecular structure that allows them to insulate down to -4F

- Get Full Safety with Vibram boots that work well for heavy-duty jobs, including oil and gas, industrial, and agriculture.

- Energy-absorbing heel region, limiting the impact on the floor while walking.

- Expanded design with a comfortable fit in a particular toe area for grip and safe landing.

- Help with traction

- Lightweight

Customer Reviews and Scores!

- 100% Comfortable

- Odor-Free

- Strong gripping insole

- Sweat-wicking material

- Slippery in watery conditions

- Tear out from heels after 3-4 uses in rain storms

5- Timberland Pro Men’s Powerwelt Wellington chemical-resistant leather boots

Specification

- 100% Full grain Leather upper

- Imported

- Rubber sole

- ASTM-rated steel safety toe

- Adaptive Comfort® cover

- The shaft measures approximately Calf High from the arch

- Goodyear Welt Cast-Bond™ Construction

- The boot opening measures approximately 9.25″ around

Features

- These timberland chemical-resistant boots have Polyurethane Slip/Oil Resistant Outsole

- Waterproof

- Oil resistant

- Rigid material to withstand harmful chemicals

- Provide excellent protection against the weather and other outside factors

- The premium Everguard leather upper stays look great

- Resistant to abrasions

- The mechanical and chemical bond resulting from the Goodyear Welt Cast-Bond construction is another way to know that these boots provide outstanding protection

- Designed for easy pulling with the grip of the fingers

- The Ladder Lock outsole radius enhances the durability and traction of the outsole

- Non-slippery

- OrthoLite footbed keeps your feet comfortable

Customer Reviews and Scores!

- 100% Lightweight

- Good for an hourly standing job or to kick shovel

- Cozy for cold conditions

- Size issues

- Non-comfortable insole

- No sweat-wicking insides

- Wearing Socks is a must

6- Carhartt Men’s 6″ Energy Black Waterproof Composite Toe CME6351 Industrial Boot

Specifications

- AX Suede Top Cover Material

- Sturdy Ground Force Rubber sole

- Black oil-tanned leather upper construction.

- EVA midsole

- Pulsion Energy Rebound inbuilt Foam

- Single density PU foam

Feature

- CAD designed based on 120,000 3D foot scans to bring you the best possible insole.

- Provides 30% more grip to reduce foot slip

- Thick Rubber Outsole for slip resistance

- Ax Suede top cover material provides 30% more grip

- Helps reduce fatigue on your feet and heat

- Made of Storm Defender, a waterproof breathable membrane to keep your feet protected from outside moisture

- Grip traction for flexibility with every step

- Lightweight proprietary EVA midsole

- Two layers of foam provide soft cushion as well as shock absorption

- The composite safety toe is wide to give you room for comfort and safety

Customer Reviews and Scores!

- Comfortable for longer walks

- Disperses compression design

- Safe and steady for dangerous work

- Reduce foot slip & fatigue

- Sturdy construction for rigid environment

- Waterproof

- Slip-resistant rubber outsole

- The only issue reported is the laces keep coming undone

7- Muck Boots Chore Oil, Chemical Resistant Steel Toe Boots!

Specifications

- Honeywell proprietary RDR compound

- 5 mm neoprene

- Imported

- 3D breathable air mesh lining

- SRC Rated slip-resistant outsole

- Heat resistant (300ºC) rubber outsole

- Lenzi non-metallic puncture-resistant midsole

Features

- Neoprene material provides comfort and flexibility, along with excellent waterproofing, shock absorption, and heat retention properties;

- Adjustable size to your foot shape to resist blisters and chafing

- 100% Waterproof

- Fully lined with 5mm neoprene for flexibility

- Steel toe reinforcement

- Additional triple rubber toe reinforcement

- Quadruple rubber heel reinforcement

- Reinforced arch support

- Extended rubber exterior for protection

- Easy to clean rubber overlay

Customer Reviews and Scores!

- Stable & durable sole

- Premium rubber construction

- Comfortable to wear for hours

- Offers improved traction on slippery surfaces

- Resistant to most oil-based fluids and other chemicals

- 100% Flexible

- Relatively heavy

8- Oliver 65 Series 6″ Leather Chemical-Resistant, Men’s Lace-Up Work Boots

Specifications

- SPR (Superior Performance Ranchwear) Leather upper with TPU (Thermoplastic Polyurethane-used in the safety footwear) SAFETY Cell

- Material: Leather + rubber outsole

- Qflex Zero puncture protection

- Kevlar stitching

- Toe Type: Steel toe

- Closure: Lace-up

- Safety Features: Chemical-resistant, puncture-resistant

Features

- Made with high-quality leather material, ensuring long-lasting durability.

- Synthetic rubber protects against impacts and compression in hazardous work environments.

- Designed to resist a wide range of chemicals, protecting your feet from spills and splashes.

- Equipped with a puncture-resistant sole, preventing sharp objects from penetrating through the sole and injuring your feet.

- Gives you a secure and adjustable fit, allowing you to customize the tightness according to your preference.

- Features a cushioned insole and padded collar, providing all-day comfort during long work shifts.

- The outsole is designed to provide superior traction on various surfaces, reducing the risk of slips and falls.

- Electrical hazard protection offers protection against electrical hazards, minimizing the risk of electrical shocks.

- Includes a breathable lining which is helpful to wick away the moisture, keeping your feet dry and comfortable.

- The outsole is resistant to oil, preventing it from deteriorating when exposed to oil spills.

Customer Reviews and Scores!

- Excellent protection from acid

- Durable shock-absorbing rubber midsole

- Comfortable cushioned insole, padded collar, and breathable lining offer comfort for extended periods of wear.

- Slip-resistant

- Versatile design, suitable for a wide range of industries

- Limited color options

9- Carhartt Men’s 8″ Composite Toe CME8355 Industrial Chemical Resistant Waterproof Boots

Specifications

- 100% Leather

- Imported

- Rubber sole

- Composite Safety Toe

Features

- Composite, non-metallic Safety Toe gives protection against impact and compression hazards.

- Maximum arch support to reduce foot fatigue during long days on the job.

- Lightweight proprietary EVA midsole provides energy recovery and absorbs foot strike impact.

- Keeps feet dry and protected in wet conditions.

- Offers ample ankle support and stability.

- Provides excellent traction on various surfaces with its slip-resistant outsole.

- Protects against electrical hazards in the workplace.

- Features cushioned insoles for all-day comfort.

- Its padded collar and tongue add extra comfort and prevent chafing.

- Provides protection against various chemicals and hazardous substances.

- Goodyear welt construction enhances the boots’ durability and allows for easy sole replacement.

Customer Reviews and Scores!

- Premium hazard Defender Leather

- Breathable

- Lace design for perfect fitting

- Durable shock-resistant rubber sole

- Heavy in weight

- Some users may find that the boots require a break-in period to achieve optimal comfort.

10. Servus Comfort Technology 14″ PVC Chemical-Resistant Steel Toe Boots For Work

Specifications

- Outer Material: Polyvinyl Chloride (PVC)

- Sole: Synthetic

- Closure: Pull-On

- Heel Height: 1-inch

Features

- Steel toe offers reliable impact protection

- Contoured heel cup reduces heel slippage

- Provides excellent protection from mud, rain, chemicals, and impacts

- Comfortable for all-day wear

- Waterproof construction keeps feet dry

- Resistant to degradation, ensuring durability

- Adjustable height for a customized fit

- Lightweight design reduces fatigue

- Arch and heel support for added comfort

Customer Reviews and Scores!

- Soft & Flexible

- Lightweight

- Washable

- May not be suitable for extreme temperatures

Editor’s Recommendation: What is the Best Chemical Resistant Work Boot?

With numerous choices, selecting the best chemical-resistant work boot can be overwhelming. Many hours were spent testing and comparing many boots to ensure that only the best could be selected for my pick.

I have carefully evaluated the top picks and recommend “Oliver 65 Series 6″ Leather Chemical-Resistant Puncture-Resistant Steel Toe Men’s Lace-Up Work Boots” to simplify decision-making.

This pair stands out in its superior protection, comfort, Durability, and style. The best thing about these chemical-resistant leather boots is its TPU SAFETY cell reinforcement surrounding the foot from toe to heel, adding extra resistance to cuts and abrasions that normally tear or rip the leather.

Let’s explore why it’s the editor’s top choice.

Buyer’s Guide: How Can I Test the Best Chemical Resistant Boots for Work?

When investing in chemical-resistant boots, it’s crucial to ensure their effectiveness. In this section, I will enlighten you with a comprehensive buyer’s guide to help you test the shoes for their chemical resistance capabilities.

Research and select boots with the appropriate chemical resistance

Before testing, ensure that the shoes you have chosen are designed to withstand the specific chemicals you will be working with. Look for boots made from materials such as neoprene, PVC, or rubber, which are commonly used for chemical resistance.

Review manufacturer’s specifications

Check the boots’ specifications to understand their chemical resistance capabilities. Pay attention to the types of chemicals they resist and any limitations or recommended usage guidelines.

Conduct a visual inspection

Examine the boots for any signs of damage or defects before conducting the chemical resistance test. Look for cracks, punctures, or weak areas that may compromise the boot’s integrity.

Prepare a sample of the chemical

Choose a small sample of the chemical you will be working with, ensuring you have it in a controlled and safe environment. When handling the chemical, follow all safety protocols and wear appropriate protective equipment (PPE), such as gloves and goggles.

Perform the immersion test

Dip the boots into the chemical sample, submerging them completely. Keep them immersed for a specific period, typically following the guidelines provided by the manufacturer.

Observe the boots during and after immersion

While the shoes are submerged, monitor them for any signs of degradation, discoloration, swelling, or softening. These could indicate that the boots are not adequately resistant to the chemical. After the specified immersion time, carefully remove the shoes from the chemical and examine them for any changes.

Evaluate the boots’ performance

Compare the boots’ condition before and after the test. If the shoes maintained their structural integrity, they likely provide good chemical resistance. However, if you notice any significant changes, such as material breakdown or compromised seams, the boots may not be suitable for working with that specific chemical.

Repeat the test if necessary

If you are testing multiple chemicals or want to ensure the boots’ effectiveness over time, repeat the immersion test with different chemicals. This will help validate the boots’ resistance capabilities across various substances.

Consider professional testing

If you require more comprehensive or accurate results, consider sending the boots to a professional testing laboratory. These facilities have specialized equipment and expertise to conduct thorough chemical resistance tests.

Keep records and make informed decisions

Document the results of your testing, including the chemicals used, immersion times, and observations. This record will help you make informed decisions about the suitability of the boots for your work environment and ensure the safety of yourself and others.

Remember, chemical resistance can vary depending on factors such as concentration, temperature, exposure time, and the specific formulation of the chemical. Always prioritize safety and follow relevant regulations and guidelines when working with hazardous substances.

What are Chemical Resistant Boots Used for?

As the name suggests, chemical-resistant safety boots are specifically designed to protect the feet and lower legs from exposure to various chemicals. They are made from materials that resist various hazardous substances, including acids, alkalis, solvents, oils, and other corrosive substances.

They are constructed for various industries and occupations where workers may come into contact with chemicals during their daily tasks. Some typical applications include

Industrial Manufacturing

Chemical-resistant boots are commonly used in industries such as chemical manufacturing, pharmaceuticals, petrochemicals, and oil refineries. Workers in these industries often handle corrosive chemicals, and wearing chemical-resistant boots helps protect them from potential spills or splashes.

Laboratory Work

Laboratories dealing with hazardous chemicals, such as research labs, testing facilities, and medical laboratories, require workers to wear chemical-resistant boots. These boots provide additional protection in case of accidental spills or leaks.

Agriculture and Pest Control

In agricultural settings, chemical-resistant boots are used by farmers, pesticide applicators, and workers involved in handling fertilizers, herbicides, and pesticides. These boots protect against potential chemical exposure while working with these substances.

Waste Management and Cleanup

Workers involved in waste management, hazardous material cleanup, or environmental remediation often encounter harmful chemicals or toxic substances. Chemical-resistant shoes are an essential part of their daily routine to minimize the risk of exposure.

Automotive and Maintenance

Mechanics, automotive technicians, and maintenance workers may encounter various chemicals, including fuels, oils, lubricants, and cleaning solvents. Chemical-resistant boots protect in case of spills or splashes in these environments.

The primary purpose of chemical-resistant shoes is to safeguard the wearer’s feet and lower legs from chemical hazards, reducing the risk of chemical burns, skin irritations, and other injuries. It is essential to select boots that meet relevant safety standards and provide adequate protection based on the specific chemicals and substances encountered in each work environment.

Who Needs to Wear Chemical Resistant Boots?

Chemical-resistant shoes are not limited to a specific group of professionals. Several individuals across various industries can benefit from wearing these boots. The following individuals may need to wear chemical-resistant boots:

- Chemical plant workers

- Laboratory technicians

- Petrochemical industry workers

- Oil refinery workers

- Pharmaceutical industry workers

- Pesticide applicators

- Farmers

- Waste management personnel

- Hazardous material cleanup workers

- Environmental remediation workers

- Automotive technicians

- Mechanics

- Maintenance workers

- Industrial manufacturing workers handling corrosive substances

- Research lab personnel

- Testing facility employees

- Medical laboratory staff

This is not the whole story; other professions or industries may require chemical-resistant boots based on the specific hazards and substances encountered in those settings.

What Features Are Necessary for Best Chemical Resistant Work Boots?

Certain features are essential in the best chemical-resistant work boots to ensure maximum protection and comfort. Now I’ll tell you the features you should look for when selecting the best chemical-resistant work boots. The following features are for the best chemical-resistant work boots:

- A contoured heel cup reduces heel slippage

- Solid outer pattern

- Injection molded PVC with Triple Density Technology

- Wide steel shank

- Cushion bed sole

- SRC-rated, with a firm grip

- Purofort premium material

- Steel toe

- Rubber outsole

- Cushioned insole for comfort

- Moisture-wicking or sweat-wicking lining

- Secure and adjustable closures (laces, zippers, etc.)

- High ankle support

These characteristics are crucial in ensuring that chemical-resistant work boots provide sufficient protection against chemical exposure while offering comfort, durability, and safety in diverse work environments. When choosing chemical-resistant boots, it is vital to assess the specific requirements and hazards of the workplace carefully.

How are Chemical Resistant Boots Tested? [Lab & Other Tests]

The nature of different job roles and the potential hazards individuals are exposed to during work necessitate the development of appropriate Personal Protective Equipment (PPE). The primary objective of PPE is to provide a range of advantages that ensure proper protection and promote optimal health conditions for those who utilize it.

Testing for Terminologies Depicting Chemical Resistance

In the first part of the testing process, work boots undergo a comprehensive evaluation to determine their chemical resistance capabilities. This involves assessing various terminologies and criteria that indicate the protection the boots provide against chemicals.

Degradation Test under Laboratory Conditions

The second testing phase involves subjecting the work boots to a degradation test in a controlled laboratory environment. The boots are exposed to specific chemicals during this test to simulate real-world scenarios. The tester carefully monitors the time it takes for the boot’s materials to break down and cease to act as an effective insulation barrier between the wearer’s feet and the given chemical.

Certification for Chemical Resistance

If the work boot withstands the effects of multiple chemicals for a sufficient duration during the degradation test, it successfully passes the second test and is designated as “chemical resistant.” This label signifies that the work boot offers high protection against a range of potentially hazardous chemicals.

Degradation and Permeation Tests under Laboratory Conditions

The third and final testing phase involves conducting degradation and permeation tests on the work boot in a laboratory setting. Similar to the second test, the boot is exposed to various chemicals. If the boot exhibits resistance against three or more chemicals over time, it is certified as a chemically resistant work boot.

By undergoing this comprehensive three-part testing process, chemical-resistant work boots can be evaluated for their ability to withstand chemical exposure and provide reliable protection to the wearer.

What are the Benefits of Wearing Chemical-Resistant Boots?

Workers in the chemical industry may face the following problems:

- Constantly walking on hard surfaces leading to foot, knee, and back pain

- Exposure to hazardous chemicals that can damage their boots and pose serious health risks when in contact with the skin

- Risk of having their toes crushed by heavy tools or objects falling

- Potential for slipping and falling on slippery surfaces, resulting in severe injuries

Wearing chemical-resistant boots offers several benefits beyond protecting against chemicals. Here we’ll check the advantages of wearing these boots regarding on-the-job safety. The benefits of wearing chemical-resistant shoes include:

- Protection against chemical exposure

- Prevention of chemical burns and skin irritations

- Minimization of the risk of chemical spills or splashes

- Safety from corrosive substances

- Reduced risk of slip and fall accidents

- Shield against hazardous materials

- Enhanced workplace safety

- Compliance with safety regulations and standards

- Comfort and support for extended periods of wear

- Resistance to abrasion and chemicals

- Electrical hazard protection

- Prevention of foot fatigue

- Waterproof properties to keep feet dry

- Anti-static properties for static discharge safety

- Protection against punctures and sharp objects

- Improved grip and traction on slippery surfaces

- Breathability to maintain foot freshness

- Thermal insulation against extreme temperatures

- Overall foot and leg protection in hazardous environments

FAQs

How can I maintain and clean my chemical resistant boots?

To maintain and clean your chemical-resistant boots, wipe off dirt and debris, use a mild soap or detergent with water, scrub stubborn stains gently, rinse thoroughly, air dry, and apply a suitable conditioner or protectant for the material.

What is the Ideal Height for Chemical Resistant Working Boots?

The ideal height for chemical-resistant work shoes depends on the level of protection needed. Generally, boots that cover the ankle or go higher provide better protection against chemical splashes and spills.

What kind of insulation is needed for Chemical Resistant Work Boots?

Chemical-resistant work boots may require insulation such as rubber or neoprene to protect against chemical hazards. These materials offer excellent resistance to chemicals and provide an effective barrier.

What Kind of Safety Toes are Needed for Chemical Resistant Work Boots?

Safety toes for chemical-resistant work boots can vary depending on the job requirements. Common options include steel toes for heavy-duty protection, composite toes for lightweight alternatives, and alloy toes to balance strength and weight.

Should I buy Chemical Resistant Boots with Laces or without Laces?

Laced boots offer a secure fit and ankle support, while laceless boots provide convenience and reduce trip hazards. Slip-on or zip-up boots are quicker and easier to put on and take off, saving time and effort, especially when frequently removing or changing footwear. Consider comfort, workplace regulations, and potential contamination when making a decision.

Closing Remarks!

Choosing the Best chemical-resistant boots for work is crucial for ensuring safety in industries where exposure to hazardous chemicals is a constant concern. In this article, I have explored and shared the top 10 picks for 2025, provided:

- A buyer’s guide.

- Discussed chemical-resistant boots specifications

- Uses and benefits of chemical-resistant boots.

- Highlighted the necessary features and testing methods.

I have tried my best to pick the best pair available on Amazon so you can buy your favorite boots without any hassle. I acknowledge that there may be other excellent choices that I might have overlooked. Therefore, you should share your feedback or recommendations as they will be comprehensive and valuable information to fellow buyers.

You may also be interested in:

The author specializes in the work boot niche, providing insightful reviews and advice on the best footwear options for durability and comfort. With a focus on helping readers find the perfect work boots, the author’s content is a valuable resource for anyone in the market for high-quality, reliable footwear.